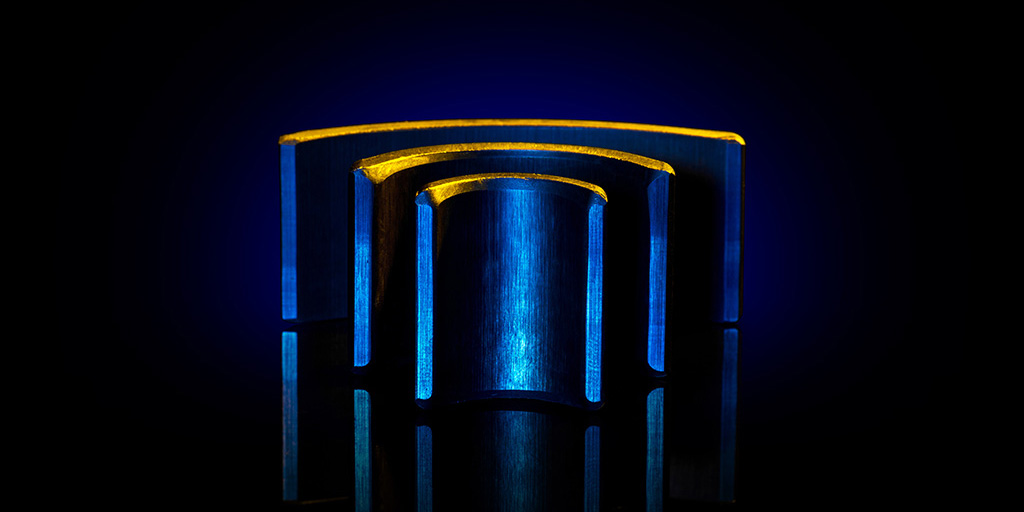

Magnetic segments

Exceptional material properties make TRIDELTA ferrite magnets suitable for use in the automotive industry as well as for application in industrial systems. TRIDELTA ferrite magnets are of unique quality, high performance parameters and economic efficiency. Specifically made for the drive systems of our customers, our magnetic segments are essential to the development of pioneering technologies and products.

We develop and produce powerful permanent magnets for use in DC motors, domestic appliances or specific industrial drive systems. On request, we also produce high-end applications and magnets of specific designs and different material grades.

TRIDELTA magnet solutions offer extremely high efficiency and appropriate potential savings: fairly cost-effective production, reliable quality, our flexibility and simple logistics are the basis for optimized processes along the entire supply chain. Every year, over 45 million quality-tested ceramic permanent magnets for EC and DC motors are shipped from our factory.

All from a single source: from the raw materials to the finished products

We manage the complete manufacturing process, from the provision of raw materials to the quality testing of the finished products. Unique in Europe, we implement the full process chain of magnet production directly at our site in Hermsdorf (Thuringia). This means that our customers can take advantage of all benefits and maximize efficiency.

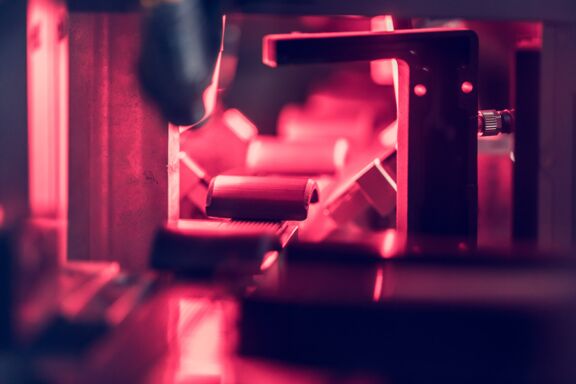

Steps in the production of magnets

Raw material: Iron oxide and strontium carbonate

- Dry mixer (EIRICH)

- Wet mixer (Leubner)

- Cost saving by uniform basic material for magnetic powder and magnetic segments

Ø 3…12 mm

- Dry and wet granulation for homogeneous calcining to ensure complete conversion to strontiumhexaferrite

Calcining in gas-fired rotary kilns

- Throughput: 450 kg/h

- 3 similar kilns for reliable delivery to customers – total throughput: 2,200 kg/h

Dry milling with rotating sifter

- Grain sizes ≤ 20 µm

- Air classifier for grain size setting

Tumbling or attritor grinding mills

- Continuous DRAIS mills

- Grain sizes ≤ 1 µm

- Optimized grain distribution according to grinding technology

- Potential 2-step milling for smaller grain sizes

Anisotropic wet pressing

- Equipment: 15 presses

- Capacity range: 70t / 125t / 230t

- Automatic removal

- Tools made inhouse by the Tridelta Group

- Direct injection for optimum cavity filling

- High number of of cavities (up to 48)

- Long life time tools (1 million shots / cavity)

Drying and sintering

- Sintering temperature: 1230 °C

- 15 electric furnaces for optimum temperature settings

- Short sintering cycle

- Computer-monitored drying

Pre-grinding / finishing

- Equipment: TROWAL

Positive effect on magnets:

- Reduced chipping

- No burrs

- Finishing to optimum size

- „Tested” mechanical strength

Equipment: COMEC grinders

- High-precision guide tools and grinding wheels

- Combined processing for higher precision: foot & width / inside & outside radius

- Third station for additional working steps (foot angle …)

Final steps:

- Automated quality testing: visual inspection / geometry check

- Packaging and storage

- Dispatch

Our customers receive more than a product from us; we give them quality and unique service:

- Highest product quality according to IATF 16949:2016

- Complete quality control by vision systems

- In-house research and development department for magnetic materials

- Aftersales management and support for the implementation of your machines and systems

- Optimized logistics processes for Europe

- Cost-saving reusable and practical disposable packaging

- Small batch series and mass production

Service and technical data

Magnetic segments for specific requirements in industry

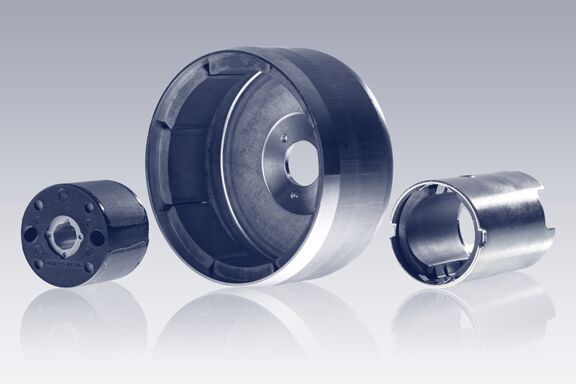

Automotive uses

Requirements on magnetic segments in the automotive sector are highly complex. TRIDELTA magnets find application in fuel pumps, DC motors and actuators, seat adjusters and fans. Our high-precision magnets are also suitable for sophisticated uses and brushless motors.

Drives and domestic appliances

Our magnets are the components of choice for drives, domestic appliances, ventilation systems or industrial products.

Special-design magnets

Many of our customers face applications with very particular technical challenges: This is where magnet solutions of special design are the right approach. Reliable and competent development guidance is an essential factor on the way to the optimum magnet solution to your project.

Our experts assist you in giving your idea a concrete shape, in selecting the suitable material parameters and defining the target specifications.

If you have questions about our products or you need a specific magnet solution: